About Boilers Part 2: Components of a Boiler

In our last article we discussed the definition of a boiler. Now let’s go a little further in depth. This article defines the basic components of a commercial or industrial boiler. Components can vary between boilers based on the specific pieces of equipment and functions. Therefore, this article is broken into two sections. The first section defines the three main components of a boiler. Then, the second portion of the article lists and defines additional components. It is important to note that some of these additional components may not be present in all boiler types.

Estimated reading time: 7 minutes

Table of contents

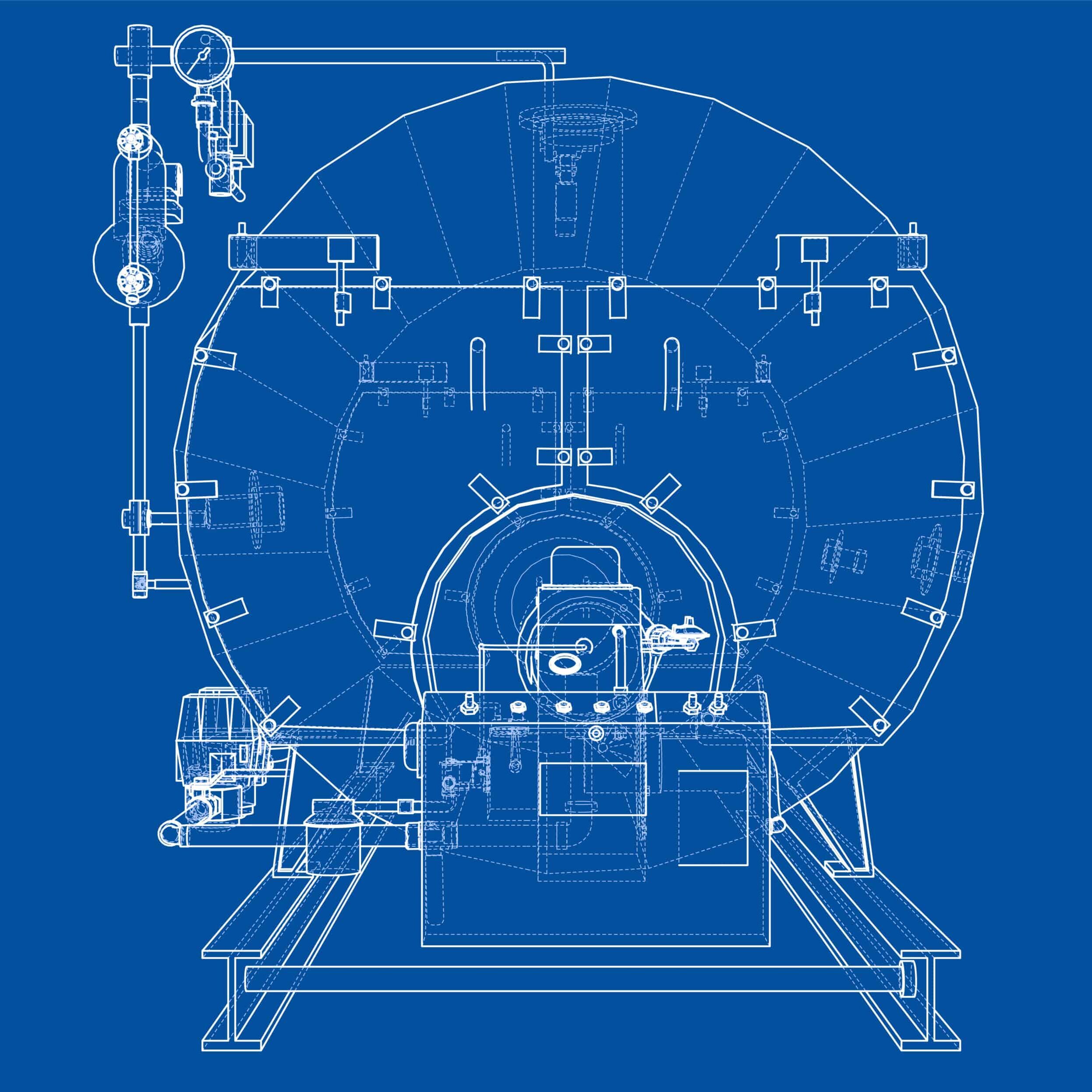

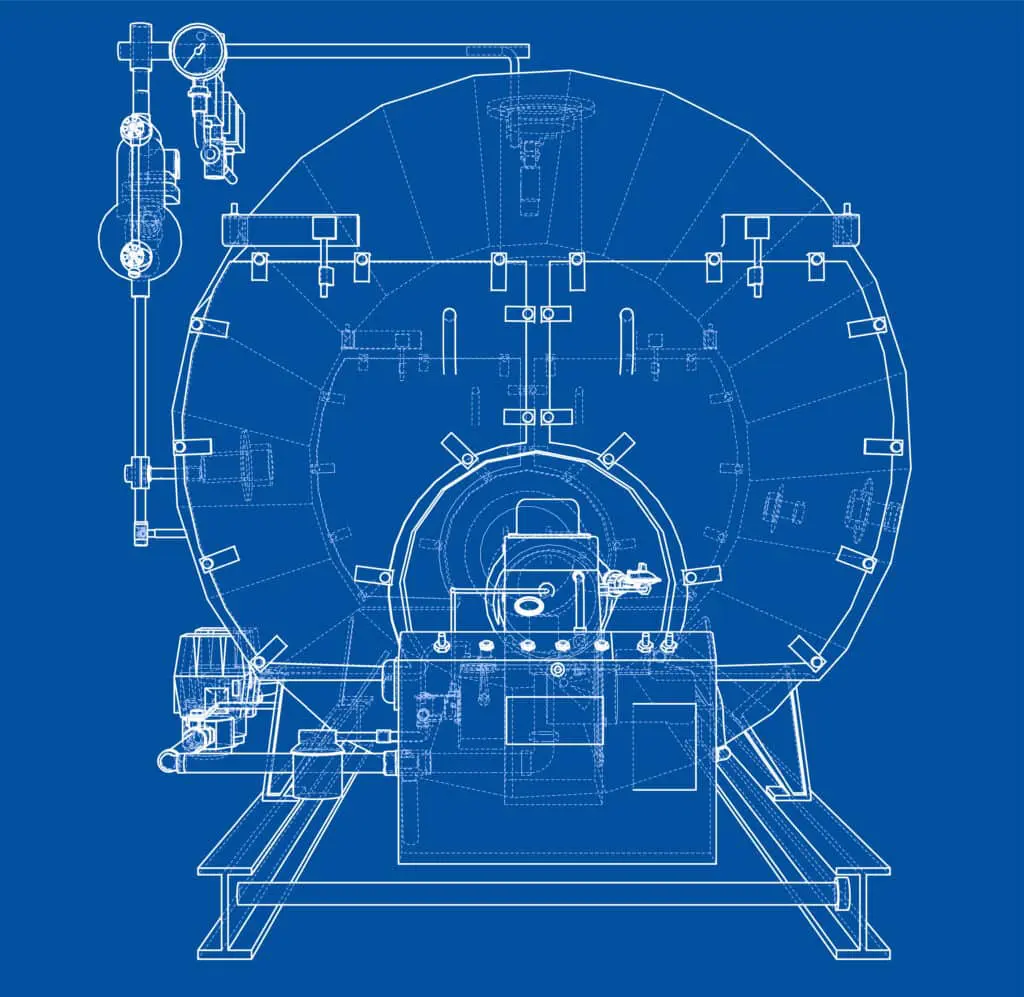

The Main Components of a Boiler

The three main components of all boilers are the burner, combustion chamber and heat exchanger.

Burner

One of the most important parts of a boiler is the burner. This is where the mixing of the air with the fuel source happens, resulting in the combustion which provides the necessary heat to heat up the fluid.

The burner provides heat input by combustion of a heat source. In other words, it initiates the combustion reaction within the boiler.

The way this particular component operates is that thermostats will send messages to the burner electronically when the system needs to produce heat. And then, fuel will pump, by a filter mechanism, to the boiler from an outside source — usually an adjacent fuel tank. A nozzle on the burner turns this fuel into a fine spray and ignites it, which creates the reaction in the combustion chamber.

Combustion Chamber

As the name suggests, a combustion chamber is the part of a boiler in which the fuel/air mix burns. For this reason, the combustion chamber is usually cast iron, and the temperatures inside will rise to several hundred degrees. This process usually occurs in a very short amount of time. After the combustion, the heat generated in this chamber transfers to the boiler’s heat exchanger.

Heat exchanger

A heat exchanger is a component of a boiler that allows heat to be exchanged between two fluids or substances, usually water and gas, without letting the substances mix together. The heat exchanger of boiler allows the heat from the burner to heat the water in system. The job of the heat exchanger is to carry the heat from the burner to the water without having direct contact with the water. It’s a similar idea to boiling water in a pot.

The heat exchanger transfers the heat produced by the burners within the combustion chamber to the water in the boiler. Heat exchangers can be made up of a variety of elements, including bundles of steel tubes, cast iron or copper lines. The elements need to be made of very sturdy material that is able to withstand high temperatures, last a long time and transfer heat efficiently. The process begins with hot gas and cold water, but because of the heat exchanger, the process ends with cooler gas and hotter water. All this transformation happens without the two substances even having to meet.

The Other Components of a Boiler System

Depending on the type and function of your boiler system, you may see some or all of the following components. These components are listed in alphabetical order.

Aquastats

Aquastats are the components in the boiler responsible to send the right signal to the burner about when to stop or when to start the process. They know the right time based on the temperature of the fluid in the boiler.

Backflow Valve

Backflow valve acts as a safety unit, allowing the flow of the fluid only in a single direction

Circulator pumps

The circulator pump is the component that pushes the hot water out through the supply lines to the radiators or other distribution lines. The circulation pump plays a crucial role in the functioning of your boiler and must be well maintained to ensure the system is working as efficiently as possible

Controls

The system controls allow the user to set water temperature, air and fuel supply mixtures, internal pressure and ignition. The controls regulate how often the burner fires, the quality of the mixture of fuel and oxygen, the rate at which it uses the fuel, and how hot the water will get. The controls are also an important part of the safety system of your boiler.

Uncontrolled, high-pressure steam can be incredibly dangerous. Well-maintained system controls help to keep your boiler completely safe. By making sure that the internal pressures within it don’t go too high, the water stays within a safe temperature range and the system continues to operate properly.

Deaerators/Condensers

A deaerator is a device that removes oxygen and other dissolved gases from liquids. Meanwhile, a condenser is a heat exchanger that removes the latent heat from the exhaust so that it condenses and can be pumped back into the boiler. Deaerator and condenser tanks are only used in steam boiler systems and not in hot water and hot oil boilers because, in these tanks, the fluid is always in on the liquid form. The construction of these two types of tanks is almost identical. However, the tanks serve different purposes. There are two primary principles for this form of tank design are: thermal and vacuum.

Thermal Principle. A tank using the thermal principle connects to the atmosphere. This design is normally used in smaller plants. Here, the steam is used to maintain the tank water temperature at around 105°C, which removes air from the water.

Vacuum Principle. In this principle, an ejector pump creates a vacuum in the tank. This causes the tank water to start boiling because of the low temperature, which in turn removes air from the water. This principle is normally for steam turbine applications.

Economizer

An economizer is a heat exchanger that is in the exhaust from a boiler. Or in the exhaust funnel of the main engine of a ship. Pump requirements differ greatly, depending on where the economizer is installed.

Exhaust stack

Exhaust stack also known as the chimney or flue. The exhaust stack safely expels spent fuel away from the building’s exterior. An exhaust stack may look like a traditional brick built chimney, or it might be a series of metal pipes. The exhaust stack must be safely constructed so that dangerous gases such as carbon monoxide are diverted away from the interior of your property. You must also make sure it isn’t expelled near windows and doors. It’s also important that they are not constructed in such a way that could allow downdrafts of powerful winds to re-enter your commercial property.

Expansion Tank

This small tank is responsible for protecting the boiler from excessive pressure and ensures its safety along the process.

Supply lines

Hydronic heating systems use piping to deliver the heated water or steam to the distribution points, and the supply lines are the pipes that distribute the hot water or steam to distributor. These parts of boiler are pipes that are responsible for delivering the heated stream of fluid to the distribution points in the boiler.

Refractory

Refractory refers to refractory materials that are used for filling any gaps and/or openings that may be around the fire box. This helps ensure the fire stays in the fire box.

Return lines

When the water cools, or the steam cools and changes states back to water, the return lines bring this water back to the boiler for re-heating. Return lines are responsible for bringing the cooled fluid or the cooled steam (which changes its state back to its liquid form) back to the boiler to heat it up again.

Superheater

A superheater is an integral part of a boiler. Superheater is placed in the path of hot flue gases from the furnace. The heat recovered from the flue gases is used in the steam before entering into the turbine. The primary purpose of the superheater is to increase the temperature of saturated steam without raising its pressure.

About Us

Powerhouse Combustion & Mechanical Corporation is a full service provider of Mechanical and Combustion Services. We hold a B license with a C-4 Steam/Hot Water Classification. Our goal is to be the premier boiler and mechanical service provider in Southern California. Therefore, we strive to maintain excellence in service where all others fall short. For example, we always have service technicians on call-to provide 24/7 boiler service.

We focus on our client’s best interests at all times. In doing so, we provide exceptional service and value. Our team is always available. Powerhouse provides 24/7 Boiler Service 365 days a year.

Powerhouse Combustion & Mechanical Corporation is based in Southern California. Our current service area includes all of Southern California and portions of Central California.

Next Up

Join us next time for part 3 of the About Boilers series. We examine the types of facilities where you can find boiler and the various functions they serve.

Related Links

Sources:

https://www.linquip.com/blog/parts-of-boiler-and-their-function/

http://www.boilers.guide/key-components-of-boilers/

https://blog.goldstonehvacr.com/insight/top-components-in-a-boiler-system/